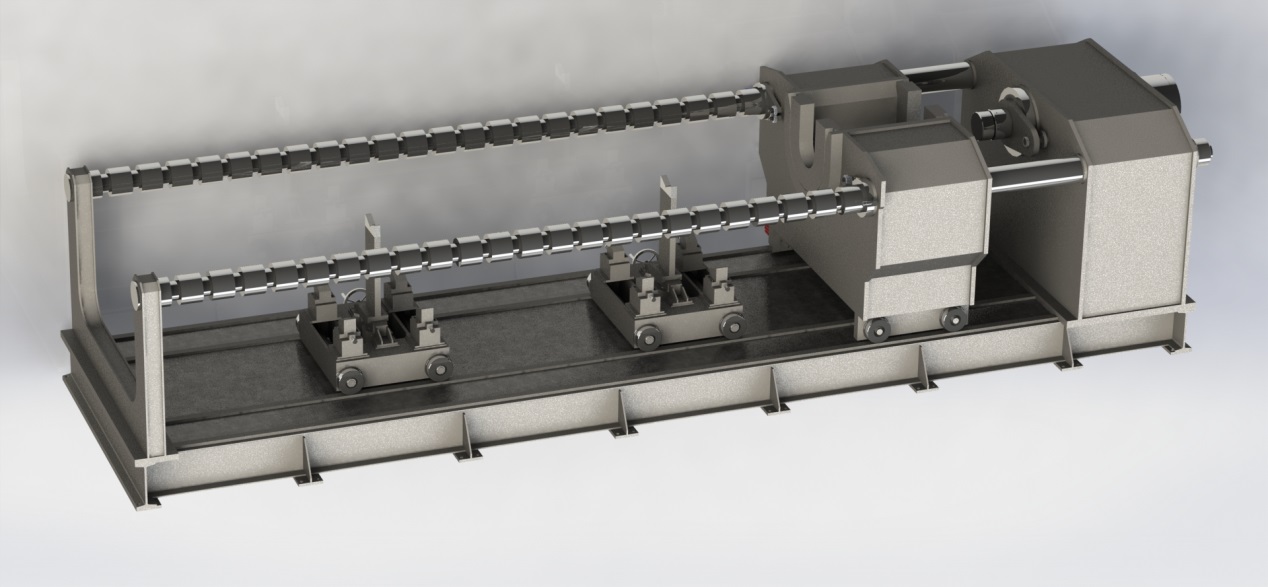

Horizontal Hydraulic Press for Mining Application Use

1. Application Scope

The Horizontal hydraulic press is applicable for dismantling and assembly of sub-assemblies of gear units, drums, wheels, dismantling of hydraulic couplings, brake drums and motor bearings etc. It’s also applicable for the mounting and dismounting of the mining rolling stock shaft and wheels. The press is widely used in the maintenance workshop of the mining and electric maintainance companies.

2. Technical Parameters

1) Maximum cylinder force: 200 tons ~ 600 tons available for options2) Number of ram cylinder: 1 set

3) Maximum piston stroke: 800 mm

4) Opening of the movable column: 600 mm

5) Distance from movable column to ram: 360mm ~ 4960 mm

6) Ram cylinder piston rod:

Fast Approach speed: Approx. 25 mm/s

Pressing speed: Approx. 6 mm/s

Retreat speed: Approx. 48 mm/s

7) Number of support trolley 2 sets

8) Maximum load capacity of each trolley: 10 tons

9) Maximum hydraulic system pressure: 31.5 Mpa

10) Total installed capacity: ≤ 25 kW

(Remarks: The above parameters are indicative and can be modified as per customer’s actual requirements.)

3. Machine Structure Description

1) The horizontal hydraulic press is mainly composed of machine frame, ram cylinder, caliper mechanism, support trolley, hydraulic system, electrical control system and tooling.

2) The machine frame consists of chassis, cylinder column, movable column, rear column and support rods. The Cylinder column and movable column are combined together via two support rods to form a force frame. The rear column is only to support these two support rods.

3) 2 Caliper mechanisms are installed on movable column to lock the movable column in the groove on the support rods.

4) The 2 support trolleys are used to hold the workpiece during operation. The support height can be manually trimmed.

5) The press is controlled through the button control station.

3) 2 Caliper mechanisms are installed on movable column to lock the movable column in the groove on the support rods.

4) The 2 support trolleys are used to hold the workpiece during operation. The support height can be manually trimmed.

5) The press is controlled through the button control station.